浏览原职位详情

- 职位介绍

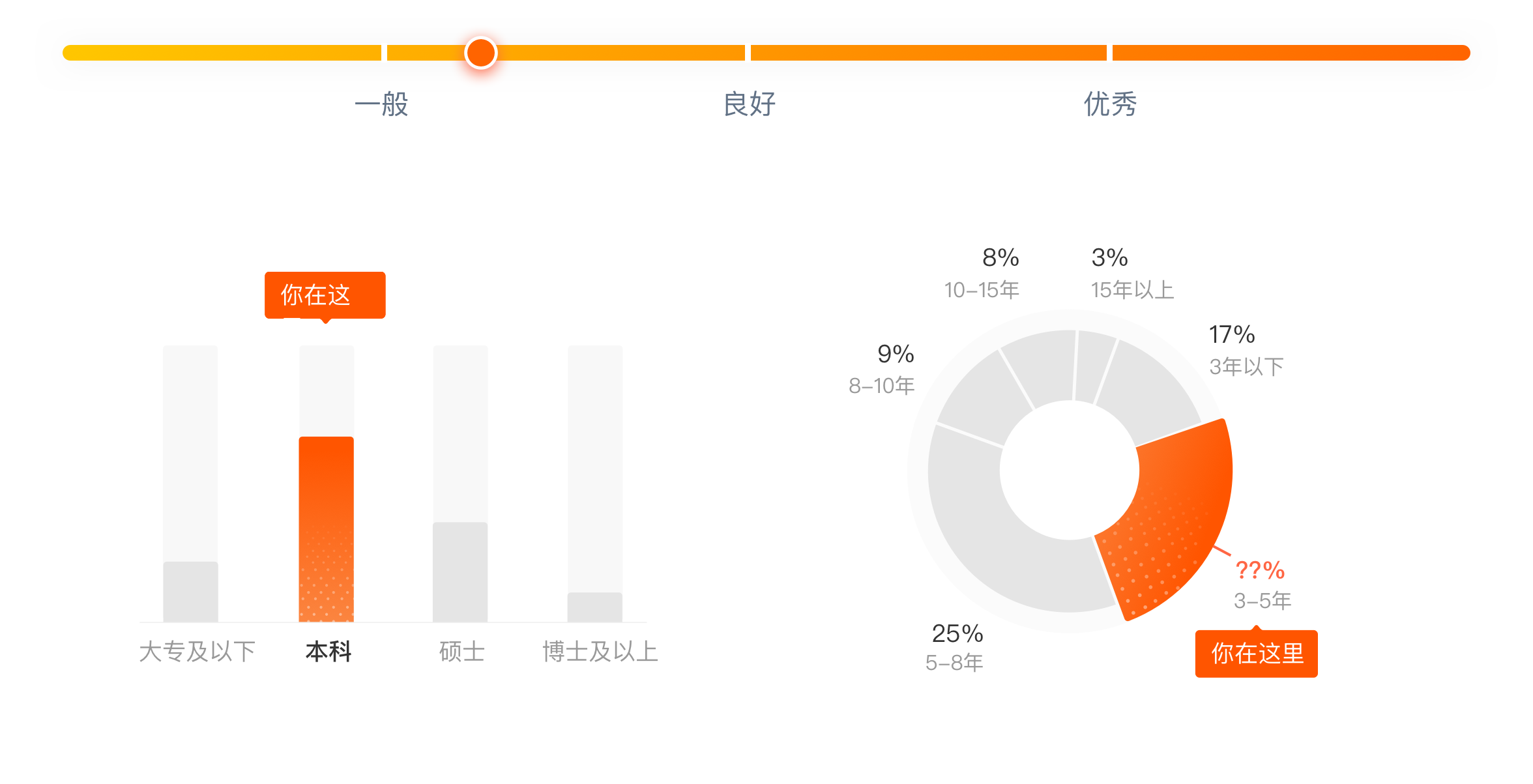

- REPORTING TO: Material Quality Leader REPORTS: IQC Supervision MISSION & IMPACT Responsible to ensure right quality of components for assembly process. Support Operation in terms of problem analyzing and problem solving to the supplier. Interact with Supplier Management in case supplier transfers, new products and escalations. SCOPE Key Responsibilities ● Drive supplier quality improvement to achieve Zero defect at site level; ● Determine the right incoming quality tools, methods, content and team; ● Get supplier’s claim analysis and action plan in less than 5 days via official claims system; ● Validate supplier’s claim action plan implementation in less than 10 days via official claims system; ● Share supplier quality claim knowledge and experience across; ● Monitor supplier performance and supplier part quality; ● Give Quick response to VS in terms of supplier incident at Value Stream; ● Support in internal quality analysis; ● Release PPAP in case of tool replenishment or renewal; ● Conduct/support supplier audits; ● Define Incoming Quality Control plan for incoming goods; ● Handle PPAP samples, organize measurement, initial assembly on the line validation; ● Drive continuous improvement process (CIP) together with VS; ● Comply with WABCO rules and policies, including Supplier Quality Assurance Manual; ● Proactively initiate actions or initiatives at supplier to support target achievement ● Handle COPQ process ● Be responsible for approving documents with safety related content (i.e. PPAP attachments) Output ● Supplied quality performance ● Supplier COPQ ● General Quality Improvement with suppliers ● Guiding of investigating and problem solving Metrics ● Supplier Incidents ● Supplier PPM ● Supplier related Customer claims ● Deployment of Supplier quality assurance programs Internal Interactions – Supplier Management, BUs, Functions External Interactions – Customers, Suppliers, External Laboratories EXPERIENCE & SKILLS Experience ● Degree in Engineering ● Minimum 3 years experience in Quality ● Automotive experience in matrix environment Skills ● Advanced Product Quality Planning (APQP - AIAG) ● Analytical Skills ● Communication Skills ● Handling of specific measurement/ control equipment ● ISO 19011 - Auditing Management Systems ● ISO 9001/ IATF 16949 ● Knowledge about reading process documentation (e.g. work instruction; control plan) ● Knowledge about MS Office ● Knowledge about eQuality (WABCO tool) ● Knowledge about SAP ● Knowledge about SRM (Supplier Relationship) ● Knowledge of manufacturing processes ● Knowledge of PLM (Product Lifecycle Management) ● Knowledge of Quality tools ( Automotive quality standards - SPC/MSA/FMEA) ● Knowledge of Root cause analysis tools (8D, Fault Tree Analysis, Pareto, Statistical Tools, etc.) ● Knowledge regarding the Product Safety Act ● Lean tools knowledge ● Production Part Approval Process (PPAP - AIAG) ● Production Process & Product Approval (PPA - VDA 2) ● "Project Maturity Level Assurance (MLA/RGA - VDA) (Maturity Level)" ● Reading skills of technical drawings and documents WABCO SPECIFIC COMPETENCIES P[ACE] makers ● Be Authentic ● Foster Engagement ● Leverage Difference ● Cultivate Collaboration ● Empower Accountability MOBILITY LOCATION Qingdao TRAVEL REQUIREMENTS 30% 电子件物料/供应商质量管理

猎聘温馨提示:

- 1. 如您发现平台内招聘方存在以下违规行为的,请立即举报

-

- a. 扣押您的身份证件或者其他证件;

- b. 要求您提供担保人、担保金或者以其他名义向您收取财物( 如培训费、体检费、资料费、置装费、押金等);

- c. 强迫您入股或者向您集资;

- d. 以招聘名义牟取不正当利益;

- e. 发布虚假招聘广告信息;

- f. 存在其他损害您的合法权益的行为。

- 2. 如您应聘的岗位属于涉外劳务合作/海外岗位的,请务必核实招聘方对外劳务合作资质取得情况,同时注意自身资金安全,防范招聘欺诈。

- 了解更多安全防范知识>

猜你喜欢

王女士

人力资源经理

闫先生

人力主管

江女士

招聘专员

赵先生

项目负责人

郭先生

总经理

马女士

TAqPartner

金女士

Talent Attraction Specialist

魏先生

猎头顾问

杜女士

招聘经理/主管

李女士

人力资源经理

1

2

3